18th HZS50 Concrete Plant to Uzbekistan

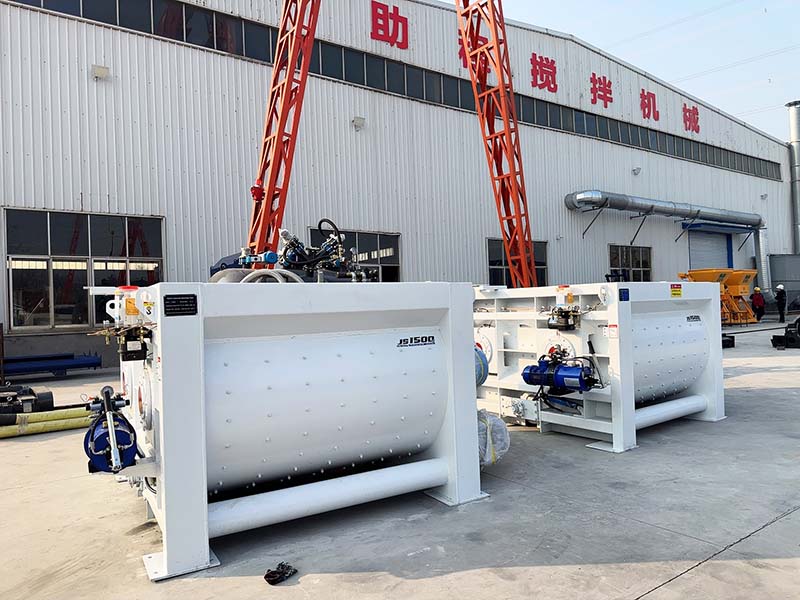

We are delighted to announce a significant milestone in our company's journey: the 18th set of our HZS50 concrete batching plant has been successfully dispatched and is now on its way to Uzbekistan. This shipment is more than just another export; it is a powerful testament to the unwavering trust our clients place in us and a reflection of the growing demand for reliable construction solutions in the Central Asian market.As Uzbekistan continues to modernize its infrastructure—building new roads, bridges, and urban communities—the need for high-quality, consistent concrete has never been greater. Our HZS50 plant is designed precisely to meet this demand, offering a perfect blend of efficiency, durability, and precision.Our HZS50 concrete batching plant has earned its reputation as a reliable workhorse in the industry. Here is why it continues to be the preferred choice for projects in Uzbekistan and beyond: 1. Superior Mixing Quality: At the core of the plant is the JS1000 twin-shaft concrete mixer. This system ensures that every batch is mixed evenly and thoroughly, producing a homogeneous concrete mix that meets the strictest structural standards....