180m³/h Concrete Batching Plant to Liaoning

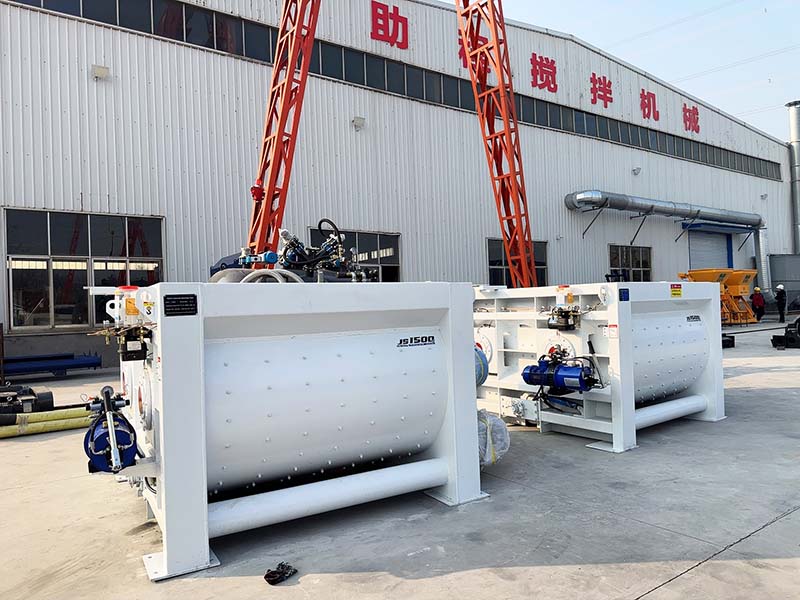

In a significant move to bolster construction capabilities in Northeast China, a state-of-the-art HZS180 concrete batching plant has been successfully shipped to Liaoning Province. This high-capacity mixing facility, capable of producing 180 cubic meters of concrete per hour, is set to become the backbone of major infrastructure and commercial building projects in the region . The HZS180 ready mix concrete plant represents the pinnacle of modern mixing technology, utilizing a twin-shaft compulsory mixer (model JS3000) to ensure exceptional homogeneity of the concrete mix . Whether the demand is for dry hard concrete, fluid concrete, or high-strength mixes for critical load-bearing...